Wera UK's Solutions Specialist visited a major boiler manufacturer to witness the main production lines for boilers and heat pumps whilst also seeing other manufacturing facilities such as the press shop. This allowed us to get an informed perspective on the operations involved and any potential problem areas that Wera could help solve.

A report was then drafted that focuses on a new production line for boilers. Implementation of the recommended products will set the correct standard form when the production line is first signed off – ensuring optimum production rates from day one. This is an extract from that report.

The implementation of the correct Wera screwdriver bit and holder will reduce the rate at which members of the production team get through bits. This not only reduces the cost of consumables for the boiler and heat pump production lines, making them more profitable – but also reduce downtime caused by swapping bits; therefore, increasing production rates.

Along with our Z-bits currently being used on site, Wera offers 5 different types of bits engineered for use with specific applications. Our BiTorsion Extra Tough bit will provide the best results for the assembly of the boilers as it is specifically designed for threaded screws as well as being designed for use with non-impact power tools. These bits also feature our Take It Easy Toolfinder, which means the profile and size of the bit are easily identifiable, even whilst in the holder. This means stations can easily be identified to what fitting they are set up for and removes the likelihood of the wrong size bit being used for screws, which could lead to damaged fittings or excessive bit wear.

For optimum results the bit should be used with our 897/4 R BiTorsion holder. BiTorsion holders by Wera have a torsion spring that absorbs low peak loads during screwdriving jobs. The combined use with BiTorsion bits and their torsion zones extends the service life of the tool considerably. These torsion zones will even increase the service life of the standard Z bits on site.

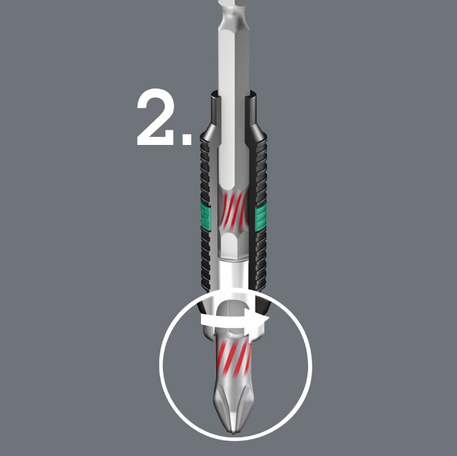

Wera's Rapidaptor technology allows bits to be attached without any need to actuate the sleeve. Once pushed in the bit is automatically locked in creating a secure wobble free hold. The removal of the bit is simple, just by pushing the sleeve forward. This enables rapid bit change with just one hand – making life for the operators easier and reducing downtime. A free turning sleeve also allows for the thread to be started by hand reducing the likelihood of cross threading leading to scrap components.

Some features of this website need your consent.